Offering the most advanced silk screen printing processes for plastic parts

If you require color matching, patterns, logos and other specifics, an injection molding secondary process may be needed. Silk screen printing can add details, images, text and logos to a part.

For over a decade, we’ve developed applications and processes that meet the very specific needs of our customers while controlling costs and turning out solid products with finishes that last.

In addition to the many painting options available through our specific systems and processes, silk screen printing plastic injection molded parts can be a desirable option when multiple colors are part of the part design.

Successful silk screen printing requires explicit knowledge

Screen printing can be an excellent choice for plastic injection molded parts when the desired appearance of the end-product requires more than one color. When applied over a plastic injection molded part, silk screening is one injection molding process that can provide a way to apply more detailed designs involving multiple colors.

Used to apply designs to multiple fabrics, including bags, t-shirts and other clothing, silk screen printing has been popular for decades. At ICOMold we’ve refined our silk screen injection molding parts process to be efficient, effective and to consistently produce excellent adhesion and a long-lasting finish.

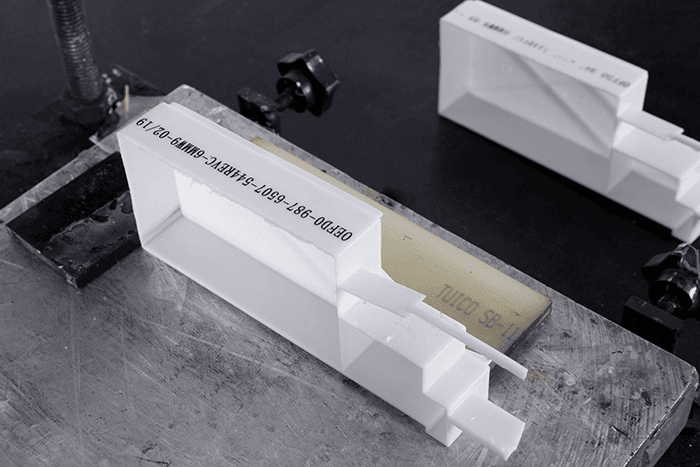

Silk screen printing for plastic injection molded parts involves the creation of a thin plastic sheet with a screen area design that allows the paint to get through to the part in the desired pattern. A separate screen is required for each paint color. The screen is placed over the part, paint is moved across it, then the screen is removed, leaving a thin layer of paint.

Limited by only the part size and shape, material ingredients and other chemical composition considerations, this method of applying paint allows creativity, detail and virtually unlimited color options.

Silk screen printing services as an injection molding secondary process

Following the injection molding process, we can offer any number of effective paint and finish options for many kinds of plastic parts. In some cases, screen printing can bring the most desirable appearance while providing a long-lasting finish.

For more details and finishing options for your injection molding parts, see our list of other Injection molding painting processes.

Our plastic injection molding design experts can help you and your team evaluate all the options and make the best choice for achieving efficient and effective painting processes designed to deliver the results you need with a quality bond you can have confidence in.

Preparing injection molded parts for silk screen printing

There are plenty of chemical composition and processing factors that must be considered before choosing and designing plastic injection molded parts finishing methods. Factors like the addition of additives in the resin production process can affect painting results. A good bond can be achieved by understanding these factors – and taking the time and care to properly prepare the surface of the plastic parts.

Another concern when it comes to screen printing is the potential for high levels of contamination in the injection molding process. We’ve developed complex procedures for overcoming the challenges that can come with deburring and extensive overspray, as well as other steps involved in some injection molding processes. At ICOMold we’re experts, not only in mold building and manufacturing, but in ensuring successful injection molding secondary processes.

Many plastics used in injection molding are predisposed to generate electrostatic surface charges. This attracts contamination like magnets. We’ve been successful at avoiding painting defects and optimizing quality adhesion by knowing the various plastics used – and consistently and carefully analyzing the entire process, from mold design, to material options, to mold preparation and part prep.

- We strive to develop tooling designs modified to downstream painting requirements in the plastic parts that will be molded

- Designing for as few cutouts as possible helps provide a better painting process

- Rounded part edges can be more easily covered with paint than sharp ones

- Because residual burrs can lead to contamination all the way into the painting booth, we keep deburring processes to a minimum

- Keeping tools extremely clean is also important, so we’ve developed systems to avoid excessive buildup of the plastics used in the injection molding process

Other ways we optimize part cleaning for silk screen printing

Getting inventive with the use of release agents, additives, filler materials and fibers we can considerably improve the processing and functional characteristics of plastic injection molded parts and their ability to bond with silk screen paints.

Fundamental to the success of screen printing is keeping these agents off the plastic part surfaces. We’ve developed proven processes and procedures that protect from this kind of transfer to the plastic parts we mold.

Silk screen printing on plastic requires surface energy, and we know how to generate it

Generally, the types of plastics used in injection molding processes present very little surface energy. This can cause adhesion challenges when it comes to applying paints and other finishes. In addition to uniform cleaning, pretreatment can go a long way toward creating a reliable surface for silk screen printing and other paint processes.

The main reason we pretreat plastics that are going to be painted is the ability to increase the surface energy of part surface and considerably improve paint adhesion.

We’ve successfully utilized CO2 snow-jet, plasma and steam cleaning, among other methods to create stronger bonding. Designed properly, these processes can reduce costs and minimize the amount of space needed. The parts cleaning process can sometimes be part of the painting line system.

Another method we can use to prepare plastic injection molded parts for painting and other secondary processes is ionization. The electrostatic charging of some plastic surfaces can be counteracted by ionization. To prepare for a good, long-lasting bond between part and paint in some non-polar plastics, like polypropylene (PP) and polyethylene (PE), we may recommend activation of surfaces through ionization before painting.

Ionization processes include:

- Gas phase fluorination

- Atmospheric pressure plasma activation

- Corona treatment and flaming

Color matching for the perfect product

We can also adjust gloss or provide more than one precise color for your design. We can utilize:

- Pantone color matching

- Physical sample color matching

- RAL color matching

Surface etching for a better silk screen printing process

Most plastic parts emerge from the molds quite smooth. When a finish adhesion is needed, the surface of the part can be etched prior to painting. To do this, we use a chemical agent to create micro-roughness and adhesion areas that will provide a better bond for the paint. This must be done carefully and correctly, or parts can be damaged, with integrity compromised.

Other surface etching methods we employ:

- Chemical reaction, including flame-induced oxidation

- Plasma conditioning

- Light-sensitive chemicals, called photosensitizers, followed by exposure to ultraviolet light

- Ozone-generating electrical corona discharge

Adhesion and multi-color designs for desirable end-products

Injection molded plastic part surface preparation is vital to any successful painting process. If the bond isn’t good and long-lasting, even the most detailed design won’t matter. Adhesion is the key for long lasting finishes. At ICOMold, we offer options that will bring you the best possible end-result and products you can be proud of.

Injection Molding Production Highlights

> Instant mold and part quote

> Low cost, quick build and quality production

> Online project management

> Trouble-free part modifications

> No size limitations

> Any commercially available material and surface finish

What is the process for injection molding production?

ICOMold’s instant online plastic injection molding quote and mold frame sharing technology enables us to simplify and shorten both the quoting and tooling manufacturing process for custom plastic injection molding.

- Load your 3D CAD file to get an instant mold and part quote

- Upon order confirmation, ICOMold starts the mold and part order process

- Tooling design review by ICOMold engineers

- Upon design approval, ICOMold begins building your injection mold

- Customer examines samples for approval

- Part production begins

Go to our plastic injection molding and CNC machining case studies page to see how we helped customers on their projects.