Injection Molded Plastic Part Design Guidelines

There can be a bit of a learning curve for design engineers who are new to designing for plastic injection molding. Understanding basic injection molding design guidelines will help designers shorten that learning curve. There are some very specific design features that must be considered in the design stage in order to avoid molding issues. These design features should be in the forefront of every engineer’s mind when starting the design process. Design changes can add time and cost to an injection-molding project, especially when the issues are not discovered until the Design For Manufacturability review. ICOMold by Fathom offers a free mold design guide as well as guidance from our team of experts to help bring your product to life.

What are the Common Design Rules in Plastic Design?

Below are the most common mold design guidelines to consider when designing for plastic injection molding:

Material – The material should always be the first item to consider. Where and how the part is used will largely determine the appropriate material. Will the part need to withstand extreme environments? Will the part be painted? Will the part come into contact with the human body? The next consideration will be material cost. Will a less expensive material be suitable for the intended application? The experts at ICOMold by Fathom will be happy to help with all material considerations.

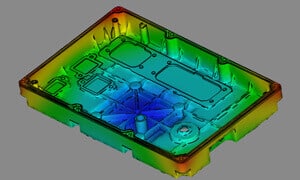

Part Wall Thickness – Like water, the molten plastic resin will always seek the path of least resistance. Part should have uniform wall thickness throughout. This will help ensure the even distribution of the plastic during the injection molding process. Uniform wall thickness will also provide better structural stability.

Gate Location – The gate is the spot in the mold where the plastic resin is injected. The gate will leave a mark on the finished part. Most gate marks can be easily removed in post processing. A good designer will place the gate in a location that is easy to remove, or better yet, in an inconspicuous spot so that it does not have to be removed. Eliminating the need for post processing will help reduce overall project costs.

Draft Angle – Good draft angles can save a customer a lot of time and money. The draft angle refers to the angle of any flat surface in relation to another flat surface. A good example would be a plastic injection-molded drinking glass. The glass is wider at the top and narrow at the bottom. The glass gets wider as it goes up, creating a positive draft angle. A positive draft angle will allow the part to be ejected from the mold easily. This will save wear and tear on the part and the mold and injection-molding machine. Draft angles should be around 1° to 2° and be considered for every wall on the part.

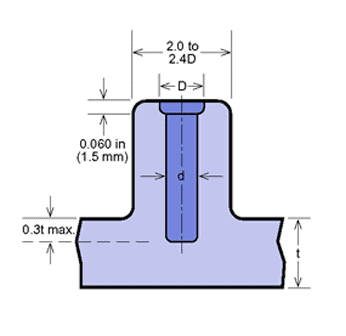

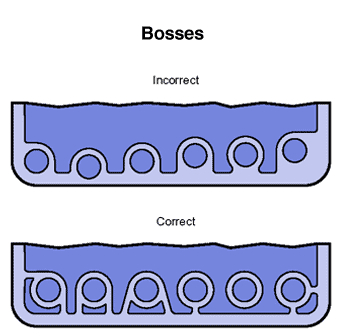

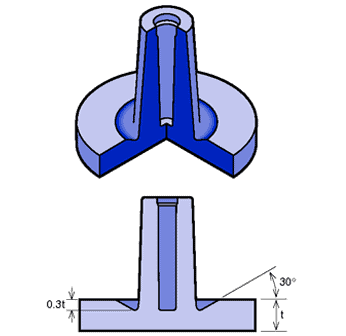

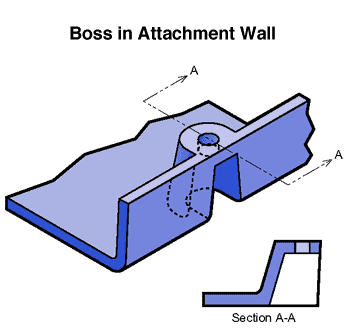

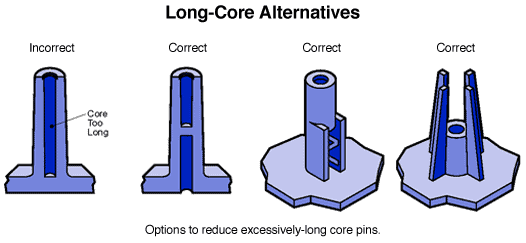

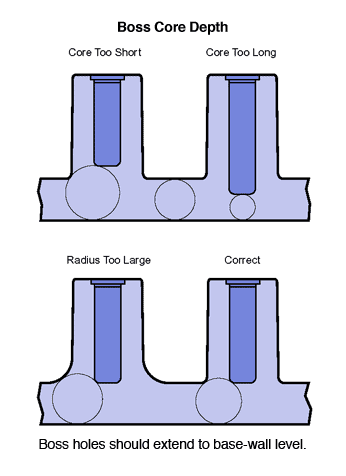

Bosses – Bosses are a common feature in many plastic parts used as points for attachment or assembly. The insert molding design guide suggests setting the outside diameter of bosses at 2.0 to 2.4 times the outside diameter of the screw or insert. The insert molding design guide also notes that designers should avoid merging bosses with sidewalls as they can form thick sections that lead to sinking. Proper bosses should have connecting ribs and be positioned away from sidewalls.

Shrinkage – All injection-molded pieces will have some shrinkage. The amount of shrinkage will depend on several factors but will mostly come down to the type of material being used. Shrinkage will happen to every plastic injection molded part because plastic will contract as it cools. Some materials can be adjusted to reduce shrinkage, and the mold can be designed in such a way to take shrinkage into account.

Part Features – Will any special feature be included in the piece? Mold design guidelines will direct designers to take into account any inserts, secondary processing like overmolding, or post-processing like painting or hot stamping. Finishes for the product should be considered as soon as possible in the design process. Texture can be added to the mold to aid in painting or other post-processing. In many cases, the texture will be essential to the plastic finishing process.

The experts at ICOMold by Fathom have created a plastic injection molding design guide to help first-time designers. This mold design guide provides information on the most important design requirements that need to be incorporated at the initial design stage. The sample tips above illustrate the information provided in the complete injection molding design guide. Fill out the form below to download the complete injection molding design guide.