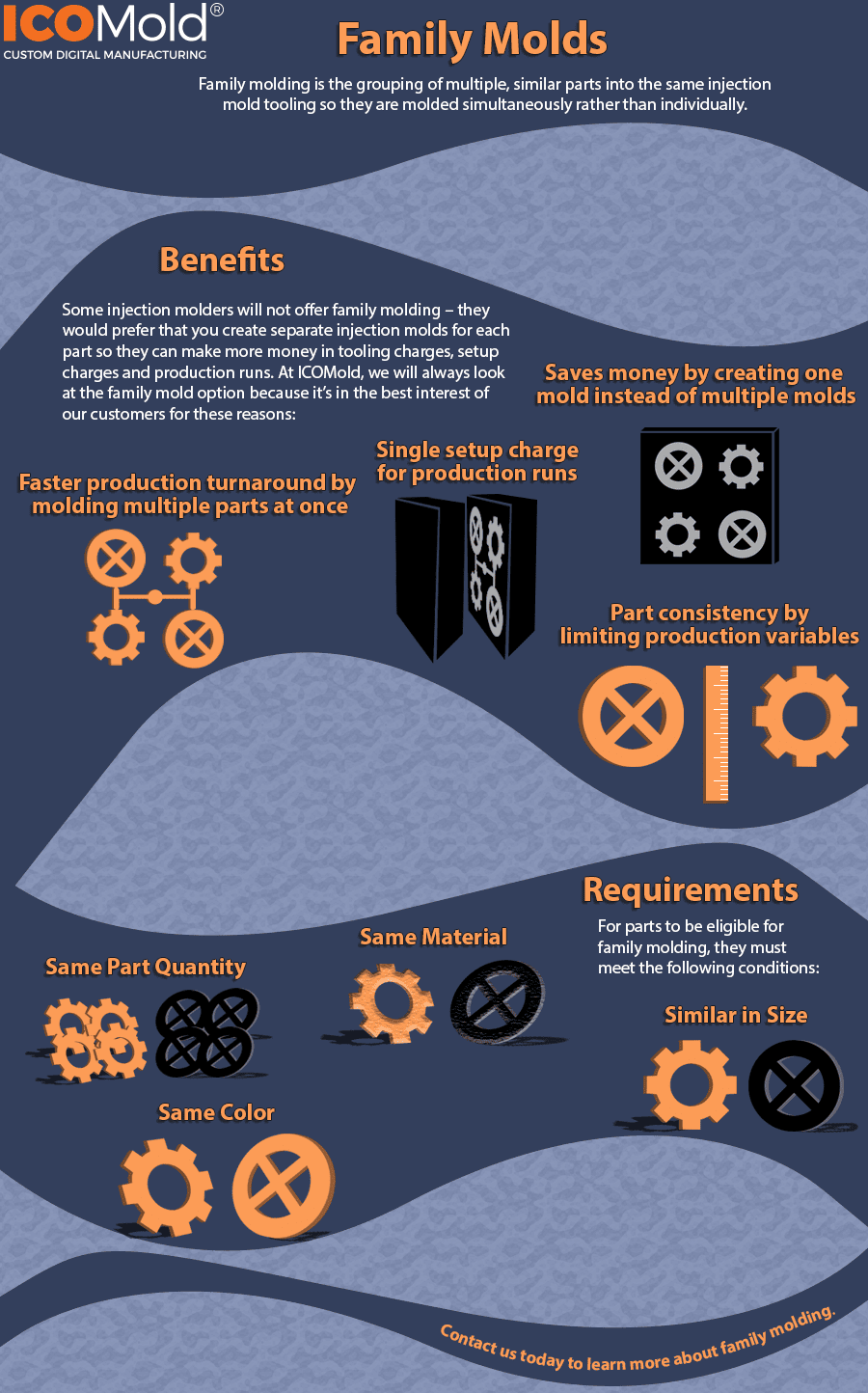

Family Molds

Family Injection Molds

Custom Plastic Injection Molding is used to make custom plastic parts. Customers in need of large production runs or production runs of related parts can save time and money but utilizing family molds or multi-cavity molds.

Family mold injection molding and multi-cavity injection molding are similar processes used to produce a set of parts that are molded at the same time. All of the parts will be similar in size, in the same color and quantities, and made from the same material.

What are the Differences Between Single-Cavity, Multi-Cavity, and Family Molds?

Single Cavity vs. Multi-Cavity Molds vs. Family Molds

Multi-cavity mold injection molding is used to make sets of the same single part. Multiple identical cavities are machined into a single mold. Instead of opening and closing the mold for one part, the mold opens and closes to produce multiples of the same part. This process is ideal for manufacturing large quantities of the same part very quickly.

Family mold injection molding is used to make sets of different parts that are similar or may fit together, like two halves of a single product. This process is ideal for packaging, consumer goods, automotive, or any industry in need of plastic part manufacturing in a similar vein. Family molds reduce the need to buy multiple molds to make one finished part. Both parts of the product can be made in one mold instead of machining two molds for each side of the part. This will significantly reduce the overall price tag of the project since most of the cost of injection molding is associated with machining the mold.

Do Family Molds Cost More Than Single Cavity Molds?

Multi-cavity molds and family molds will cost more than a single cavity mold because of the extra machining required. However, a family mold that can make two different, but related parts will cost much less than two, single-cavity molds that are machined to do the same. Having one mold to make multiple parts cuts down on wear and tear, increases mold longevity, and reduces the price-per-piece cost since multiple parts can be made at one time. A little bit of extra upfront cost can shave thousands of dollars off of the overall project total. Both family molds and multi-cavity molds can save customers a considerable amount of money and time.

What Are The Benefits of Family Molds and Multi-Cavity Molds?

Lower Tooling Cost

One family mold can be created with multiple cavities instead of creating multiple, single-cavity injection molds and paying the tooling cost for each one. Tooling costs are dramatically lowered by only machining one mold.

Lower Production Cost

Family molds and multi-cavity molds will reduce production costs. Production time is lowered since there is no need to switch out molds. Multiples of the same part can be created each time the mold opens. The per-piece price of each part will go down if multiple parts are produced each time the mold opens.

Easier Ordering

Family injection molds can make it easier to place orders. If a product requires a left side and a right, those parts can be machined into one family mold. The customer only has to order from that mold instead of multiple molds. This also ensures the correct amounts of parts are sent to create the finished product.

Scalability

Making one million parts with a single cavity mold would tie up machines and resources for weeks or even months depending on the length of each injection cycle. A multi-cavity mold can substantially reduce production costs and turnaround time.

Required Criteria for Family Injection Molds

Parts Must be the Same Material and Color

All parts produced in a family injection molds or multi-cavity injection molds will be the same material and color. Only one type of material can be sent into the mold at any given time. Since there are multiple cavities in the mold, all cavities will be filled with the same material. Parts that need to be different colors or made of different materials cannot go into the same family mold.

Parts Will All Be Made in the Same Quantity

This is not really a requirement but something to keep in mind when creating family molds. Every time the mold opens, the exact number of parts in the mold will come out. If the mold produces Side A and Side B to make one complete product, then each time the mold opens it will produce enough parts to complete one product. If the mold produces one of Side A and two of Side B, the customer will end up with one extra Side B every time the mold opens. This is only a detriment if there are parts left over. Family molds do not need to adhere to a 1:1 ratio. If the final product requires one of Side A and two of Side B, then utilizing a family mold will save the customer time and money.

Parts Must Have Similar Size and Volume

This is an important rule to follow when considering family injection molds. All cavities of the family mold are filled at the same time and rate. Having parts that vary in size and volume will cause issues with short shot and flash. A short shot is an under-filled mold. Flash is what happens when molds are overfilled and excess material seeps out of the mold during injection. Short shot and flash can happen in the same family mold if the cavities have too much variation in size or volume. The larger cavity will suffer from short shot as the injection machine struggles to fill the whole cavity before the plastic starts to solidify. The smaller cavity will suffer from flash since it fills up quickly. The injection machine will still be trying to force more material into the mold to fill the larger cavity. The excess material will seep out of the smaller cavity. While under shot parts are typically discarded, parts with flash can be salvaged. This excess material will usually require manual removal. Flash should be avoided if possible as it can deform the mold and shorten the production lifespan, resulting in mold failure.

Process for Family Injection Mold

ICOMold’s online quoting system enables us to simplify and shorten both the quoting and tooling process for plastic injection molding.

- Upload the 3D CAD file to get a quote for mold and part cost.

- ICOMold starts the mold and part order process upon order confirmation.

- ICOMold engineers review the tooling design.

- ICOMold begins building the injection mold after design approval.

- Customer examines samples for approval.

- Part enters production.

Family Injection Mold Highlights

> Fast mold quote

> Low cost, quick build, high quality

> Mold frame sharing technology

> Online project management

> Built to your specifications

> No size limitations with the exception that all family molded parts should be roughly the same size/volume within reason

> Any commercially available material and surface finish

Click here to view case studies from ICOMold and see how we can help with your next plastic injection molding or CNC machining project.