CNC Metal Machining

Get a CNC Machining Quote Today!

ICOMold offers a full range of Computer Numerical Control (CNC) metal machining services. Our metal milling services can be used to create part prototypes or small batch part runs. ICOMold is part of the Fathom manufacturing network with access to a wide range of CNC and injection molding machines. Speak with the experts at ICOMold to find out how we can save you time and money on your next project. Or try our online quoting system and receive an instant quote today.

What is CNC Machining?

CNC machining is a manufacturing process that uses high speed, computer-controlled, precision machines to remove plastic or metal from a blank block of material to create a part. The process is highly repeatable, resulting in the same identical part each and every time.

What Does CNC Stand For?

Computer Numerical Control (CNC) is a manufacturing process that utilizes computer controlled cutting tools. CNC machining is a subtractive manufacturing process. The cutting tools remove material from a blank block, leaving only the desired part behind. It is the same principle as a sculptor revealing the statue hidden in a block of marble. The CNC machine is controlled by Computer-Aided Manufacturing (CAM) software. Computer Aided Design (CAD) files are loaded into the CAM software. The CAD file acts as a set of directions, telling the CNC machine where and how to cut away material.

Can You Cut Metal with a CNC Machine?

Yes! CNC machines are mainly used to cut metal or plastic. CNC machining is ideal for manufacturing prototype parts and small part runs. There are several different types of CNC machines that can be used to cut metal. A CNC machining online quote is available through our instant online quoting system.

- A36 Steel Plate

- Alloy Steel 4140

- Aluminum 2024

- Aluminum 5052

- Aluminum 6061-T6

- Aluminum 6063

- Aluminum 7050

- Aluminum 7075 T6

- Bearing Bronze C932

- Easy Forming Brass 260

- Free Machining Brass C360

- Low Carbon Steel 1018

- Stainless Steel 17-4

- Stainless Steel 303

- Stainless Steel 304

- Stainless Steel 316/316L

- Titanium (Ti-6AI-4V)

How CNC Metal Machining Works

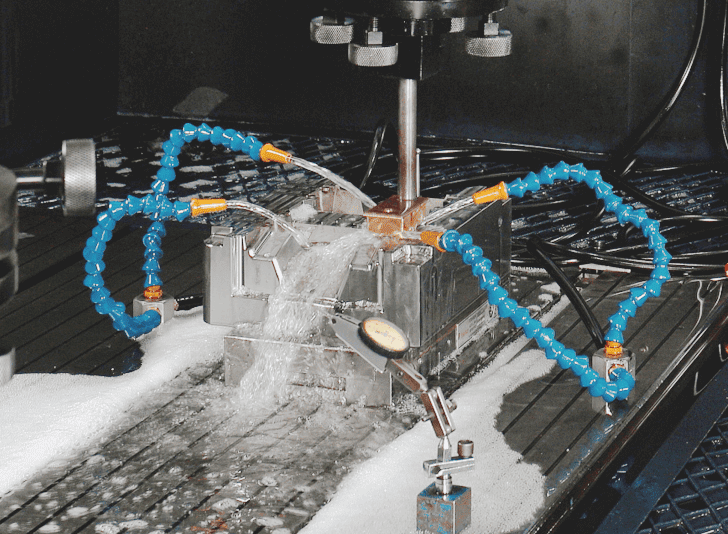

A CNC machine is given a specific set of code in the form of a CAD file. The CAD file tells the machine where and how to cut material from the blank metal block or metal sheet. The CAD file code contains a list of instructions on how to create the part. The code will first tell the machine where to place the tooltip, then how fast the tooltip should spin, and finally where and how to move the tooltip. CNC machines use coordinates on a set axis. ICOMold by Fathom use multi-axis CNC machines for CNC metal machining. Parts are cut on the X-, Y-, and Z-axes, allowing for complex geometries that would be nearly impossible with conventional machining. CNC machines cut parts with extreme precision. Each successive part will be exactly the same as the first, making replication fast and easy. Receive a CNC machining quote instantly through our online portal or call the experts at ICOMold to talk about your next project.

Benefits of CNC Machining

Get a CNC machining online quote from ICOMold today. We offer CNC metal machining services to fulfill your parts manufacturing needs. Getting a CNC metal machining online quote is easy. Simply use our instant CNC machining quote tool and get the cost estimates back in seconds. ICOMold by Fathom offers fast turnaround time for most custom CNC milled metal parts with no size limitations. Get your CNC machining online quote today or speak with the experts at ICOMold by Fathom to see how we can take your next project from design to reality.

CNC Prototyping

CNC metal machining services are ideal for creating prototype parts to ensure fit, form, and function. Part prototyping allows manufacturers to test new parts and make necessary changes before moving on to mass production. CNC metal machining is quick, relatively inexpensive, and allows customers the opportunity to get their hands on a part without the expense or time required to make a full production run. Changes are easy and inexpensive, too. Just make the design changes in the CAD file and the CNC milling shop at ICOMold will have the revised part ready for testing in no time. CNC machining quotes are available instantly through ICOMold’s online quoting system

Small Production Run

CNC metal machining services are a fast and efficient way to complete small production runs. CNC machining has many advantages over other manufacturing processes. The biggest advantage is the low cost of entry. All that is required is to complete a CNC metal machining project is a CAD file. There are no costly molds and no extended production times. Parts are cut directly on the CNC machine and will be ready to use immediately. The ICOMold CNC milling shop can have small production runs done and to the customer in a matter of days.

Form, Fit, and Function

ICOMold’s CNC metal machining provides manufacturers the opportunity to test a part for form, fit, and function before committing to a final design and entering into mass production. Having prototypes made of the same material as the final product and available for testing is an invaluable resource for designers. They will be able to hold a finished version of the final product and put it to the test long before the item enters production. Prototype parts can then be subjected to the same conditions as to final piece to ensure form, fit, and function.

The Form

CNC metal machining is a precise process and provides exact repeatability. The computer-controlled machine tools all move precisely and simultaneously on their axes to create complex, three-dimensional shapes that would be almost impossible or incredibly time consuming with manual machining. These qualities make CNC metal machining an ideal manufacturing process for projects that require a high level of precision or repetition.

The Fit

CNC metal machining can produce parts that require tight tolerances under exacting specifications. ICOMold’s CNC milling shops hold tolerances to within +/- 0.002 in. (0.05 mm) for metal parts. Customers can specify tighter tolerances on critical areas of the part.

The Function

The material being used is just as important as the design. CNC metal machining from ICOMold allows manufacturers to test prototype pieces as they would the final production parts. ICOMold specializes in custom aluminum machining as well as machining a long list of other metals. Parts made with CNC metal machining are immediately ready for use and can be subjected to any required testing conditions.

Types of CNC Machines

CNC machines are purpose-designed and built to do a specific job. The varying CNC machine designs allow our CNC milling shop to meet the demands of any customer. There are three types of CNC machines typically used for metal machining: CNC Mills, CNC Lathes, and CNC Plasma Cutters. ICOMold has several different types of each CNC machines in order to meet the varied needs of our customers.

CNC Mills

CNC mills are the most common type of CNC machine. This machine starts with a block of metal called a blank. The CNC machine removes material until only the desired part is left. The cutting tool can be directed across a three-axis system. The X-, Y-, and Z-axes are used to cut height, width, and depth from the part. The CNC machine follows the coordinates from the CAD file in order to produce the finished part. CNC mills offer exact repeatability.

CNC Lathes

CNC lathes can also be used for CNC metal machining. CNC metal machining done on a lathe is referred to as turning. The CNC lathe operates along the same basic principles as the CNC mill. A cutting tool is used to remove material from a blank block. While the CNC mill holds the block in one place, the CNC lathe spins the blank at a high speed. The computer then uses a cutting tool to remove material from the spinning blank. All cuts are identical on all sides of the blank since the block is spinning and the tool is held in one place. CNC lathes are ideal for creating cylindrical pieces. A CNC lathe uses a two-axis system, only removing material from the X- and Y-axis.

CNC Plasma Cutters

Contact the experts at ICOMold for more information on CNC metal machining services or submit your project through CNC machining online quote system for an instant quote.

CNC Metal Machining Review

CNC metal machining is an ideal manufacturing process for small runs of metal parts, especially when dealing with prototypes or low volumes. Before committing to CNC metal machining, there are several variables to consider. The hardness of metal will affect the length of time required to machine the part. Harder metals, like carbon steel, require a slower cutting speed. A slower cutting speed will take more time to remove material from the blank. Custom aluminum machining can be done nearly four times as fast because aluminum is a softer material. The type of metal can also greatly affect the final cost. Be sure to consider the type of metal and its cost when doing preliminary price estimations. The experts at ICOMold by Fathom have decades of combined experience to help guide you through your next project.

ICOMold offers several secondary processes for CNC machined components. After the metal part is machined, it can be sent for anodizing, plating, or powder coating. ICOMold specializes in custom aluminum machining but can easily work with a variety of metals to satisfy customer needs.

- A36 Steel Plate

- Alloy Steel 4140

- Aluminum 2024

- Aluminum 5052

- Aluminum 6061-T6

- Aluminum 6063

- Aluminum 7050

- Aluminum 7075 T6

- Bearing Bronze C932

- Easy Forming Brass 260

- Free Machining Brass C360

- Low Carbon Steel 1018

- Stainless Steel 17-4

- Stainless Steel 303

- Stainless Steel 304

- Stainless Steel 316/316L

- Titanium (Ti-6AI-4V)

High Quality CNC Milling Service

Quality is the cornerstone of ICOMold’s success. We believe quality comes with the commitment of engineering resources to the Quality Control Department. Our highly trained Quality Control staff ensures quality by painstakingly reviewing custom CNC milling designs and certifying raw materials. Our experts perform dimensional and appearance checks after each metal milling services, then document all results in a quality control report.

Capability:

- Fast turnaround time for most custom CNC milled metal parts.

- Various surface finishes are available.

- Tight tolerances. Within +/- 0.002 in. (0.05 mm) for metal parts.

- No size limitations.

- Receive a CNC machining online quote instantly through our project portal.

Go to our plastic injection molding and CNC machining case studies page to see how we helped customers on their projects.