What Is Plastic Injection Molding?

Injection molding is a manufacturing process used to make plastic parts. Plastic injection molding can be used for anything from manufacturing a few prototype parts up to running millions of an identical part. Plastic injection molding is ideal for making large quantities of the same part or related parts. ICOMold by Fathom provides custom plastic injection molding for customers worldwide.

What is Plastic Injection Molding Used For?

Plastic injection molding has almost unlimited manufacturing possibilities. Examples of plastic injection molding can be found in a variety of industries including consumer electronics, car parts, medical devices, tools, toys, and packaging. Post-processing applications can be used to achieve the desired finish or texture. Plastic injection molding is an economical way to mass-produce the same or similar plastic parts.

The Basics of Plastic Injection Molding

Plastic injection molding is the process of making plastic parts using molten plastic and a metal mold. Special plastic resins, known as thermoplastics, are melted and then forced into the metal mold. Molds can be made of steel, aluminum, or beryllium-copper alloy. The molten plastic fills the cavity inside the mold. The part is removed from the injection mold after the plastic has cooled and re-solidified. This manufacturing process is done with specialized injection molding machines called presses. These injection-molding machines must be able to do several key processes at the same time. First, the thermoplastic is melted and then pushed under pressure into the metal mold. The injection-molding machine must be able to hold the mold closed while it is being filled. The machine uses a clamping mechanism to keep the molds closed by applying the appropriate amount of pressure to the outside of the mold. This pressure is called clamping tonnage or clamping force. To learn more about clamping tonnage click here. The clamp is released once the part has cooled. The part is removed from the mold and the process starts over.

Low Cost: ICOMold has domestic and offshore injection molding facilities. ICOMold can leverage the offshore injection mold manufacturing facility to lower cost structure in order to offer better pricing than our purely domestic competitors.

High Quality:Our process quality systems ensure that your parts are the highest quality possible for your application.

Quick Turnaround: ICOMold offers three different shipping methods, including next day air, to accommodate any timing and budget requirements.

Online Quotes: ICOMold offers an interactive, online quotation system that provides INSTANT quotes for plastic injection molding, CNC machining, and urethane casting.

Cost of Plastic Injection Molding

The cost of plastic injection molding is dependent on several variables, including part complexity, chosen material, and the number of parts being produced. The largest expense will be in creating the mold. Simple molds can cost $3,000 to $6,000 while more complex molds will cost $25,000 to $50,000. The next variable will be the number of parts being produced. The more parts being injection molded, the less each part will cost. Each individual part can cost a few pennies to over $10 a piece. The final cost of each piece will depend on the type of plastic being used, the overall cost of the mold, and the number of parts being produced. The up-front cost for plastic injection molding can be higher than other manufacturing methods, however, the savings can be substantial considering that each piece, when manufactured in the hundreds, thousands, or millions could only cost pennies per part.

What are the Disadvantages of Injection Molding?

Injection molding is a manufacturing process designed to make hundreds, thousands, or even millions of the same part or set of parts. It is an efficient and economical way for small or large businesses alike, to mass-produce plastic parts. The only real disadvantage can be the cost of each piece when making a small number of parts. ICOMold by Fathom has access to a wide range of manufacturing processes that can be utilized to manufacture prototype or low-number part runs. Contact the experts at ICOMold to learn more about alternative manufacturing methods for prototypes or low number part runs.

Plastic Injection Molding by ICOMold

ICOMold is part of the Fathom network of manufacturers. We provide custom plastic injection molding for customers worldwide in a variety of industries. ICOMold is a low-cost leader in high-quality injection molded plastics.

Headquartered in Hartland, Wisconsin, Fathom has been in the plastic injection molding business since 2003. Our customers range from first-time inventors all the way up to Fortune 500 companies. Fathom is an ISO 9001:2015 certified injection molding company.

The Plastic Mold Manufacturing Process

The granules are slowly moved forward by a screw-type plunger and the melted plastic is forced through a nozzle that connects to the mold sprue bushing, that controls the flow of material, allowing it to enter the mold cavity through a gate and runner system.

The metal mold is kept at a lower temperature so the plastic will solidify almost as soon as the mold is filled. The part cools and hardens to the shape of the mold cavity. The two halves of the mold, Side A and Side B, or the Cavity and the Core, open up and ejector pins push the part out of the mold where it falls into a bin. The mold is then closed and the process begins again.

Injection Molding Plastic

Plastic injection molding is widely used because it can be adapted to meet almost any requirement, depending on the type of plastic being molded. Choosing the correct plastic is an important decision. Available plastics have a variety of characteristics based on their chemical make up. The intended application of the part will also determine the type of plastic that can be used. Material properties to consider include durability, flexibility, performance, texture, density, and color. Contact the experts at ICOMold for help choosing the right plastic for your next project. ICOMold keeps over 300 different plastics in stock for injection molding including:

- Crystalline Plastics

- Amorphous Plastics

- Imidized Plastics

- Polyethylene (PE)

- Polypropylene (PP)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyoxymethylene (POM)

- Polystyrene (PS)

Which Plastic is Best for Injection Molding?

The best plastic for injection molding depends on the final product. Plastics have a wide variety of characteristics that can effect how and where the part can be used. The experts at ICOMold will guide you through the process of choosing the right plastic for your project.

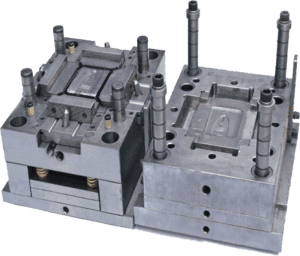

How Do You Make Plastic Injection Molds?

Injection molds are typically made with Computer Numerical Control (CNC) machining or with Electrical Discharge Machining (EDM). Traditional machining used to be the standard method of building injection molds. Those molds were carved out of metal blocks with a knee mill. Technology has since replaced traditional machining, giving way to CNC machining and EDM. CNC machining and EDM allow for more complex molds and accurate detailing while taking less time to make than traditional machining.

EDM is the newest way to make plastic injection molds. The process uses a shaped, copper or graphite electrode. The electrode is slowly lowered onto the mold surface that is immersed in paraffin oil. Electric voltage applied between the tool and the mold causes spark erosion of the mold surface in the inverse shape of the electrode. EDM is essentially a high-tech machining method that uses electricity to melt away material. The mold is immersed in oil so that any removed material will harden before re-adhering to the mold surface. EDM allows plastic injection mold makers to achieve a level of detail that would be impossible with traditional methods like milling or grinding.

EDM has become widely used in mold making industry. Many companies, including ICOMold by Fathom, offer in-house EDM services. The process allows the creation of molds that would otherwise be difficult or impossible to machine in a conventional manner. Details like ribs or square corners are easily done with EDM but nearly impossible with even the most advanced CNC machining.

EDM can only be used on electrically conducive materials. This allows pre-hardened steel molds to be shaped without requiring a follow up heat treatment. Molds can be made of pre-hardened steel, steel that is hardened after the mold is produced, aluminum, and/or beryllium-copper alloy. The number of parts being produced typically determines the choice of mold material, although there are a few variables to consider.

Steel molds will generally have a longer lifespan. The higher initial cost of a steel mold will be offset by longevity, as it is capable of producing a higher number of parts before wearing out. Pre-hardened steel injection molds are less wear-resistant than those hardened by heat treatments after they are machined. Pre-hardened steel is typically used in molds that have a lower volume part requirement. Steel molds can also be modified or repaired to extend longevity, an advantage not shared by aluminum molds.

Aluminum molds, depending on varying economic conditions and material origin, can cost substantially less than steel molds. Aluminum molds have a quick build time, and give faster cycle times due to the heat dissipation properties of the metal. Beryllium copper can also be used in areas of the injection molds that require fast heat removal, or in areas where the most shear heat is generated. Longevity and durability are an issue with aluminum molds and beryllium copper molds since both are softer metals than steel. Aluminum and beryllium copper molds will need to be replace much quicker than steel molds. Aluminum and beryllium molds also cannot be repaired or modified after machining where as steel molds can be repaired or modified to some extent.

How Complex Can You Make a Plastic Injection Mold?

Plastic injection molds can range from the simple to very complex. A simple injection mold will have two halves. After the mold is filled, the halves separate and the part is ejected. Additional processes can be added to injection molds in order to produce more complex plastic parts, specifically for part designs with overhangs and undercuts.

Molds can be augmented with side-pull mechanisms called slides to accommodate part features such as undercuts. Slides move into a cavity in a perpendicular direction from the draw of the mold halves to form the undercut feature, then stationary angle pins on the stationary mold half pull the slides away when the mold is opened.

Multiple-Cavity Molds (Family Molds)

Plastic injection molds do not need to be limited to a single part. Injection molds can be made to produce multiple numbers of the same part at the same time. An injection mold with only one impression is called a single impression or single cavity mold. Injection molds with two or more cavities of the same part is referred to as a multiple impression or multiple cavity molds. Some extremely high-volume molds – like those for bottle caps – can have over 128 cavities.

A multiple cavity mold can also be called Family Molds. A family mold will produce multiple, like-sized parts in the same quantity, color, and material. In this case, the mold will produce a set of corresponding parts each time it opens. Family molded parts are often part of an assembly, such as the top half and bottom half of a part that will eventually be assembled.

Overmolding

The process starts with an injection molded part. That part, or substrate, is then inserted into a second mold where a different material, or overmold, is added to the existing structure.

Some specialized plastic injection molding machines have two or more injection units that can overmold in a single molding cycle. Two-Shot or Multi-Shot injection molds will mold a basic shape in a base material, before the second material, is injected into the remaining open spaces to produce a one-piece, multi-material plastic part.

Overmolding is not without its limitations and is not as straightforward as simply injection molding a part out of a single material. One of the major variables in overmolding is plastic compatibility. The materials must be chemically and thermally compatible. Since plastic materials have different melt temperatures, the substrate material must have a higher melt temperature than the overmolding material, otherwise the original part would melt and deform when the overmolding material is injected.

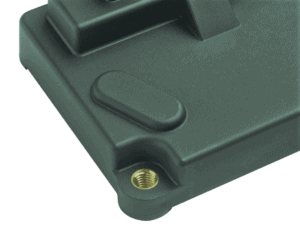

Insert Molding

Insert molding can reduce cost by embedding secondary parts into the plastic injection molding process, as opposed to installing the parts after molding. Insert molded parts are more robust when compared to staking the pieces in post-molding. This is due to the insert being encapsulated in the plastic as opposed to mechanically adhered after the molding process. Insert molding will also save money as it reduces the need for post-processing labor. Insert pieces must be able to withstand the high temperature and pressure of the injection molding process.

Insert molding is a more complex process than standard injection molding. ICOMold has extensive experience with the process and can offer customers different solutions to reduce cost and speed up production.

Are There Other Types of Plastic Injection Molding?

There are several other types of plastic injection molding beyond simple injection molding, insert molding, and overmolding. Other types of plastic injection molding include:

- Co-injection molding

- Thin-wall molding

- Rubber injection

- Low-pressure plastic injection molding

- Inset and outset plastic molding

What is Molding Cycle Time?

The cycle is the sequence of events that happens during the plastic injection molding process. The cycle begins when the mold closes and the molten plastic polymer is injected into the mold cavity. When the cavity fills, the mold maintains a holding pressure to account for material shrinkage. After that the screw turns, pushing the next shot of molten plastic into place for injection. The mold opens once part has cooled and it is removed from the cavity. The cycle is now complete and will start again.

Why is Molding Cycle Time Important?

Optimizing molding cycle time will save time and money. The faster the cycle time, the more parts that can be produced in a certain time frame. A formula can be used to determine the cycle time of injection molding. The time it takes to make a part using injection molding is calculated as:

Cycle Time = 2M + T + C + E

Where:

(2M) = Mold Open/Close Time x 2

(T) = Injection Time (S/F)

(C) = Cooling Time

(E) = Ejection Time (E)

(S) = Mold Size (in3)

(F) = Flow Rate (in3/min)

The time it takes to open or close the mold and eject the part can last from less than a second up to a few minutes, depending on the size of the mold and machine. The cooling time, which dominates the process, depends on the maximum thickness of the part.

Process Efficiency

Optimizing the injection molding process is essential. An optimized process will reduce cost while increasing quality and productivity. Some of various optimization checks include:

- Optimize the holding time by conducting gate seal or gate-freeze studies.

- Conduct a cooling time study to optimize the cooling time for an injection-molded part.

- Pressure drop studies to determine if the machine has enough pressure to move the screw at the set rate.

- Perform viscosity curves to determine injection speeds.

- Vary the melt temperatures and holding pressures to optimize the process window.

Molding Trial

A molding trial is used to get all parameters set correctly when starting a new injection-molding job. The mold technician will usually start with a small shot weight and fill the mold gradually until it is 95% to 99% full. A small amount of holding pressure is then applied, and the holding time is increased until the part solidifies, also know as gate freeze off. Gate solidification is important because it determines cycle time. The gate is the point where the molten plastic enters the mold and will be the last place the plastic will solidify. Cycle time is crucial in determining efficiency and overall cost of the injection molding production process. If the parts have sink marks, the holding pressure will be increased until they are minimized and the desired part weight is achieved. A setup sheet is produced for standardizing the process for future production runs once the settings are configured properly and the injection-molding machine is producing quality parts.

What Equipment is used in the Plastic Injection Molding Process?

Plastic injection molding machines – called presses – consist of a material hopper, a screw-type plunger, and a heating unit. Presses clamp the mold to the platen of the machine, where plastic is injected through an orifice to create the finished plastic injection-molded piece.

Plastic injection molding machines are rated by tonnage, which calculates the amount of clamping force the machine can exert. This force keeps the mold closed during the plastic injection molding cycle. The projected area of the part being molded as well as several other variables will determine the total tonnage needed. The stiffer the plastic material, the more clamp tonnage is required to hold the mold closed. Generally, four to five tons per inch are used on most plastic injection molding projects.

Today, electric injection molding machines are favored over traditional presses. Electric presses require 80% less energy consumption and offer nearly 100% repeatability. Increased demand for plastic injection-molded parts has allowed manufacturing companies to close the gap on cost even though the cost of an electric press is 30% higher than traditional presses.

Injection Molds: Aluminum vs. Steel

The material used to construct a plastic injection mold is often a question of budget and the desired end product.

Historically, injection molds were created from steel and were expensive to manufacture since the molds needed to be machined by hand. These molds were typically only used in large-scale productions when thousands of parts needed to be produced.

Today, there are several options for mold material; however, most molds are made from either steel or aluminum. Depending on certain market factors, aluminum molds can cost much less than steel molds. When higher-grade aluminum like QC-7 or QC-10 is used with modern computer equipment, it can economically mold thousands of parts. Aluminum molds also offer faster cycles and quick turnaround because of the metal’s enhanced heat dissipation.

Steel molds typically cost more to build, but a longer lifespan often offsets higher initial costs. High-grade steels like H-13 and S-7 are tough metals, withstanding the wear and constant pressures of plastic injection molding. Steel grade PAS940 is excellent at transferring heat. Stainless steel injection molds are commonly used for larger components or clear parts like lenses.

ICOMold by Fathom uses cutting-edge CNC machining and EDM to meet our customer’s exact mold specifications. ICOMold works exclusively with the highest-grade steel available to ensure mold durability and longevity.

Mold Making Services by ICOMold

ICOMold by Fathom offers multiple options for different types of injection molds based on expected production cycles and warranty. ICOMold offers in-house, start-to-finish production services for plastic injection molding. ICOMold will make an injection mold for a client and then use the mold to manufacture the customer’s parts. ICOMold also offers Export Molds. These molds are manufactured and shipped to the client to for use in their facility or a facility of their choosing. For a complete description of all in-house and export type injection molds, please visit the Mold Types page.

ICOMold injection molds are made exclusively with steel. Click here to learn more about the advantages of steel molds over aluminum molds (icomold.com/aluminum-molds/). Steel is the material of choice due to mold longevity, durability, reparability, and the ability to injection mold complex parts.

Various types of steel can be used to create plastic injection molds. While P-20 is considered the workhorse of the industry, ICOMold will also use other steel types depending on the situation and requirements.

ICOMold by Fathom can meet all of your plastic injection molding needs. From start to finish or any step in between, we can provide to expertise and guidance to get the job done correctly, quickly, and efficiently.

Why Choose ICOMold for Plastic Injection Molding and Services?

ICOMold by Fathom has been a leading plastic injection molding company since 2003. We have proudly produced plastic injection molds and plastic parts for companies in the United States, Europe, Australia, Asia and South America. ICOMold has done custom plastic injection molding projects for a variety of industries including medical, automotive, sports, hunting/camping, electronics, food/beverage, containers, packaging and more.

ICOMold’s custom molding process begins with the instant online quote system. This online system also provides quotes for CNC machined plastic prototype parts.

ICOMold provides inexpensive custom molds and injection molded plastics. We typically charge 30% to 50% less than other plastic fabricators. Our strong plastic injection molding foundation gives us the ability to avoid common mistakes, make smart decisions, and complete your next project with ease.

ICOMold by Fathom has the experience and extended manufacturing network to meet the needs of any company. The experts at ICOMold will help you confidently move forward with the design and manufacturer of your part.

ICOMold is ISO 9001:2015 certified. We have streamlined our process and produce parts with fewer defects when compared to the competition. These quality systems also allow us to offer top-notch plastic injection mold manufacturing at extremely competitive prices.

Contact ICOMold by calling (419) 867-3900 or request an instant quote for your next custom plastic molding project.

Visit the plastic injection molding and CNC machining case studies page to see how we helped customers on their projects and learn more about plastic injection molding.