Insert Molding — Plastic Injection Molding

What is Insert Injection Molding?

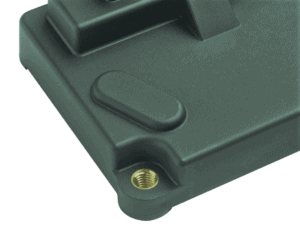

Insert injection molding is the process of forming a plastic part around a different type of material. This is typically done with simple metal objects like a nut or threaded rod. However, insert injection molding can be used to place ceramic parts, other plastic parts, motors, threaded bushings, batteries, or warning labels into the injection-molded part.

What is the Insert Molding Process?

The process starts by placing the insert into the mold. Injection molds used in the insert molding process are machined to easily receive and hold the insert. After the insert has been placed, the mold is closed, and the molding process can begin. The mold is filled with molten plastic the same as the regular injection molding process.

The part is ejected from the mold after the plastic has cooled. The inserted item is now firmly bound and integrated into the plastic part. There are many options for inserts that can be placed into the mold. Speak with an expert at ICOMold by Fathom to see how they can take your next project from design to reality.

What are the Benefits of Insert Molding?

There are two major reasons to consider insert injection molding over secondary insertion processes. The first benefit of insert injection molding is cost savings. The insert molding process will be more expensive than regular injection molding due to the increase in required manpower. However, there are significant savings by not having to handle the part a second time to manually install the inserts. While the upfront cost for insert molding will be slightly higher, the time and money saved not engaging in post processing will be significant.

The second benefit of the insert molding process is structural stability. Consider a plastic part that requires the integration of multiple threaded bushings. The bushings that have been molded directly into the part will be more structurally stable than if they were inserted post-molding. Before insert injection molding, the bushings would have to be added after injection molding with a secondary process like heat staking. These secondary processes require additional labor, adding time and cost to the molding project. Manually inserting the bushing may also adversely affect the structural stability of the plastic part. Manually inserting the bushing can also invite human error. Misplaced or misaligned bushings may cause problems if the part requires a high degree of accuracy. Insert molding would ensure that the bushing is placed the same way with the same alignment every time.

Metal Insert Molding

A third benefit to consider is using insert injection molding for weight reduction. Injection molding with inserts can produce the same functional part as one that would be made entirely out of metal. The plastic part with metal inserts will weigh a fraction of the part made entirely out of metal. Metal insert molding can be very useful in the automotive and aerospace industries where weight reduction is a priority. Threaded rods, nuts, bushings, or custom-machined metal parts can be incorporated into plastic parts to fit your design. The experts at ICOMold have decades of combined experience working with the insert molding process. ICOMold also has a robust Computer Numerical Control (CNC) machine department that can machine custom metal parts to meet customer specifications for metal insert molding.

Are There Special Considerations for Insert Molding?

Support

Can the part design support the insert? The part must have enough material around to insert to hold it securely in place. Thin walls around the insert may result in the insert breaking away from the rest of the part during production, testing or use.

Temperature

Will the insert withstand the temperature of the injection molding process? Temperature must be taken into account when using plastic inserts. The injection molding process uses high temperatures and pressure to produce plastic parts. Be sure that any insert can safely be exposed to the temperature required to melt the plastic injection material. Inserts not rated for high temperature may deform or melt entirely during the injection molding process. It is a good idea to use plastic inserts that have a higher melting point than that of the injected material.

Pressure

Will the insert withstand the pressure of the injection molding process? The amount of pressure generated during the plastic injection molding process is fairly high. Any inserts must be sturdy enough to withstand this pressure without cracking or deforming. The combination of high temperature and pressure can be detrimental to some inserts and should be taken into consideration before the insert injection process begins.

Insert Molding Applications

There are many applications to insert molding. Such applications include:

- Auto industry components

- Industrial equipment components

- Medical devices

- Couplings

- Threaded fasteners

- Electrical parts

ICOMold can help with your insert molding needs.

What is the Difference between Insert Molding and Overmolding?

Insert molding and overmolding are similar injection molding processes. Insert molding generally takes a small part, like a threaded rod or bushing, and encapsulates it within the plastic resin. The process forms one single part where the injected plastic encloses the inserted material.

Overmolding is the process of plastic injection molding a layer of plastic over the top of another plastic part. A good example of overmolding is the housing for a cordless drill. The main body of the housing is the first run or substrate of the injection molding process. After the substrate has cooled, it is placed in another mold and the process starts again. This time the softer grips and handles are overmolded onto the main body. The process forms one single part made of two different plastic materials.

Process for Insert Molding — Plastic Injection Molding

ICOMold’s online quoting system and mold frame sharing technology enables us to simplify and shorten both the quoting and tooling manufacturing process for plastic injection molding.

- Load your 3D CAD file to get your mold and part quote.

- Add your requirements for inserts in the comments, and your project manager will contact you.

- Upon order confirmation, ICOMold starts the mold and part order process.

- Tooling design review by ICOMold engineers.

- Upon design approval, ICOMold begins building your injection mold.

- Customer examines samples for approval.

- Part production begins.

Insert Mold — Injection Molding Highlights

- Fast mold and part quote (inserts must be quoted offline by a project manager)

- Low cost, high quality and fast turnaround

- Mold frame sharing technology

- Online project management

- Trouble-free part modifications

- Any commercially available material and surface finish

Go to our plastic injection and CNC machining case studies page to see how we helped customers on their projects.