Design for Moldability

When is it REALLY Necessary to Change Your Part Design?

Customers frequently tell us that they went to a competitor first, only to be told that they had to redesign their part.

It’s important to understand the difference between needing to change a design for moldability, versus the manufacturer requiring changes just to fit their way of doing things.

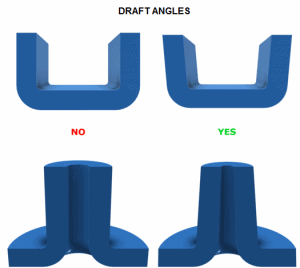

At ICOMold, we provide feedback to our customers on moldability issues like draft angles and wall thickness. These are universal requirements that every injection molder has. (Visit the Design Guidelines page on our website for moldability design tips).

But here’s the difference: Since we only use hardened steel molds, we can meet your part geometry requirements. Our competitors, who use aluminum molds, may tell you that you have to make additional design changes, but in reality it’s just to accommodate their way of manufacturing an aluminum mold.

Additionally, they have part size limitations because of their aluminum molds that we don’t have with our steel molds. And with the price of our steel tooling typically beating the price of their aluminum, it just makes sense to come to us first.

Learn more at www.ICOMold.com.