Case Study: An Inventor’s Product Development Journey

The SlingBaron: World’s First Twirling Harmonica Dryer

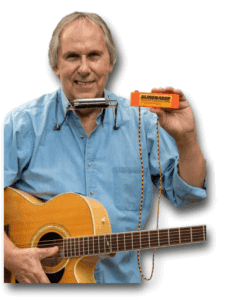

An inventor’s journey through the product development cycle can be very difficult, time-consuming and costly. It was all three for Mike J. Baron, inventor of the SlingBaron, the world’s first twirling harmonica dryer.

Mike is a longtime inventor and harmonica player who combined these two talents to develop a problem-solving product and bring it to market.

The development process wasn’t easy for Mike, but his persistence and belief in his product drove him to continually improve the SlingBaron’s design through the prototyping process.

The first prototype was made out of PVC, the second out of wood, and the third was 3D printed out of plastic. When Mike was satisfied with the design and functionality of the plastic product, he came to ICOMold for injection molded production parts and took the SlingBaron to market.