A leader in plastic injection molding

Get Online Quotes in 30 Seconds

- The world’s only 30-second injection molding quote

- Parts shipped in as little as 15 days

- Offshore prices with US contacts

Low-Cost Injection Molding Leader

The Best Brands Put Their Trust in ICOMold

Our Process is Different

And Proven Across Top US Companies

Low Cost

Offshore injection mold

manufacturing to lower costs.

High Quality

Our process and quality systems ensure high-quality parts.

Quick Turnaround

Parts shipped in as little as 15 days. We offer multiple options to accommodate your timing.

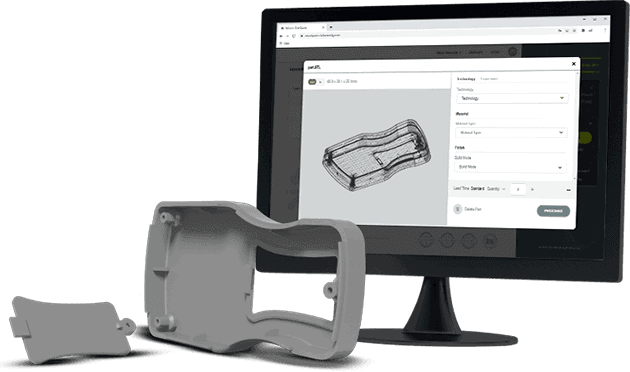

Online Quotes

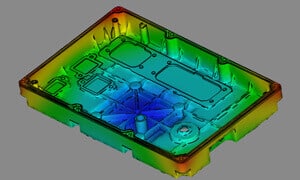

Our industry-leading technology

offers instant injection molding cost

calculation.

World Class Capabilities

Comprehensive Tooling, Injection Molding Services & More

Injection molding Services

- Production Molds

- Export Molds

- Family Molds

- Insert Molding

- Overmolding

- Compression Molding

- Rapid Molds

- Mold Manufacturing

- Prototype Molds

Materials

- Plastics

- Thermoplastics

- Polycarbonate

- Polypropylene

- PVC

- Acrylic

- Resin

- Nylon

- Glass-filled Nylon

- ABS

- Thermoplastics Rubber

- Polystyrene

- Low-Density Polyethylene

- Fiber-Reinforced Plastic

- High-Impact Polystyrene

- Acetal/Polyoxymethylene (POM)

- Many Others

Other ICOMold Services

- CNC Machining

- Urethane Casting

Other Fathom Manufacturing Platform Services

- 3D Printing

- Metal Cutting & Forming

Testimonials

Customers Validate Our Process

“We cannot say enough good things about ICOMold.”

“I received the parts today from ICOMold. They look and function great!”

“ICOMold’s quoting process was the only one to offer true instant quoting.”

Injection Molding Services

Capabilities, Resources, Quotes & More

Urethane Casting

Plastic and rubber-like materials providing the lowest cost for low volumes.

Additive Manufacturing

Get instant online 3D printing quotes through the Fathom manufacturing platform.

Compression Molding

Looking for compression molding services? Learn how ICOMold can help with your compression molding needs.

Injection Mold Making

ICOMold is here to help you with your injection molding needs. Discover what molding services are available.

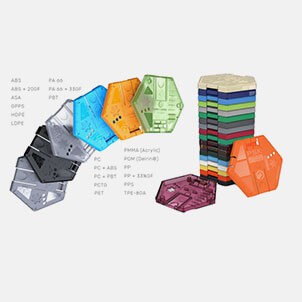

Plastic Samples

Get a plastics sample kit to compare 20 hexagons of colors and textures for only $95.

Instant Injection Molding Quote

The world’s only 30 second plastic injection quoting tool.

Design Guidelines

Plastic Injection Molding Materials

Color Selection

Learning Center

Contact Us

China Injection Mold

Rapid Molds

Injection Molding Price

Frequently Asked Questions

Answering Questions from Plastic Injection Molding to Metal CNC

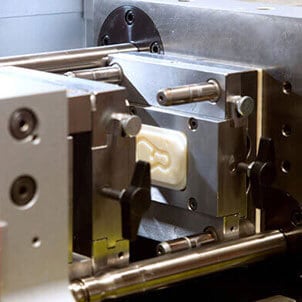

Injection molding is the process of producing various parts by injecting heated material into a mold. Injection molding can be done with many different materials such as metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. ICOMold specializes in custom plastic injection molding, CNC machining of plastic and metal, and urethane casting. Get a CNC quote or a plastic injection molding quote today!

If you’re looking for an injection molding company who can support your business needs, you should turn to ICOMold. ICOMold offers low prices on plastic injection molds and plastic parts. You can also get an instant injection mold quote and CNC manufacturing parts quotes through our online quoting and project management system. We offer fast and dependable injection mold services and trouble-free injection mold modifications. Our services include low and high-volume production molds and parts— rapid prototype injection molds, production molds, and export molds. Get a plastic injection molding quote today.

ICOMold offers several molding services such as:

Plastic part manufacturing involves many different processes and details, such as:

Finding the right company for your injection molding project does require careful research and consideration. Read about ICOMold, one of the leading plastic injection molding companies, and their process for delivering high-quality parts, fast at low prices.

Plastic mold manufacturing is the process of creating molds to mass product plastic parts. Learn more about plastic mold manufacturing.

If you are looking for a plastic molder near you, no sweat. ICOMold can service customers just about anywhere. Learn more about ICOMold.

It’s true that there are several plastic mold makers to choose from. Learn why ICOMold is the right plastic mold maker for you and your project.